RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

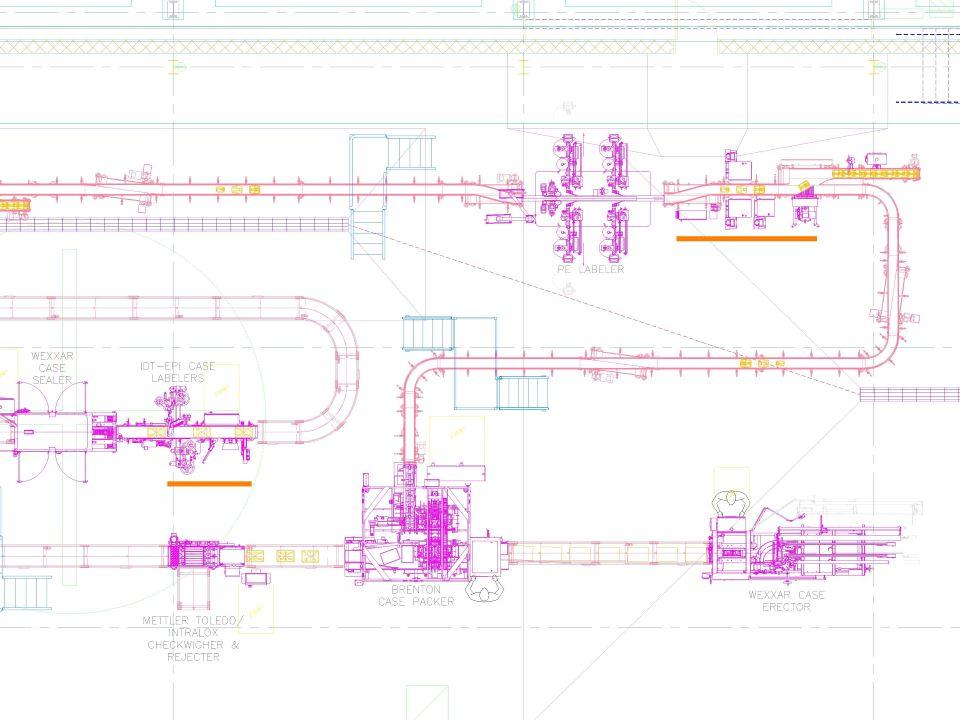

As a leading single source provider of turnkey processing and packaging lines, ProMach efficiently and cost-effectively helps customers of all sizes ship more packaged goods out the door. Our global team of technical application and engineering experts can transform individual pieces of equipment into high-performance production lines and help mitigate risk by partnering with customers to provide everything from line design to the end of the line.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreZARPAC Packaging Line Design Tools & Descriptions

- Packaging Line OEE Optimization ModelQuantitative tool whose outputs ensure that a specific line design and layout does not negatively impact OEE. Goal is machine downtime is only source of negative OEE impacts.

- OEE Optimized Machine Speed CalculatorQuantitative tool whose outputs specify the optimum operating and surge speeds for each machine in the production line. This tool helps define appropriate machine models and target steady-state speeds for each machine in the line.

- OEE Optimized Accumulation Sizing CalculatorQuantitative tool whose outputs specify the optimum location and sizing for accumulation in the production line.

- Project Management Checklist & Deliverables ScheduleComprehensive and detailed planning & execution tool that assures a project manager is addressing every key task and deliverable on schedule.

- Conveyor Motor & Gear Box Sizing CalculatorQuantitative tool that selects optimum conveyor motor and gear box sizes.

- Conveyor Chain Pull CalculatorQuantitative tool whose outputs drive selection of optimal chain types and optimal distances of chain pulls.

Zarpac's turnkey design and management services are ideal for multiple applications: