RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

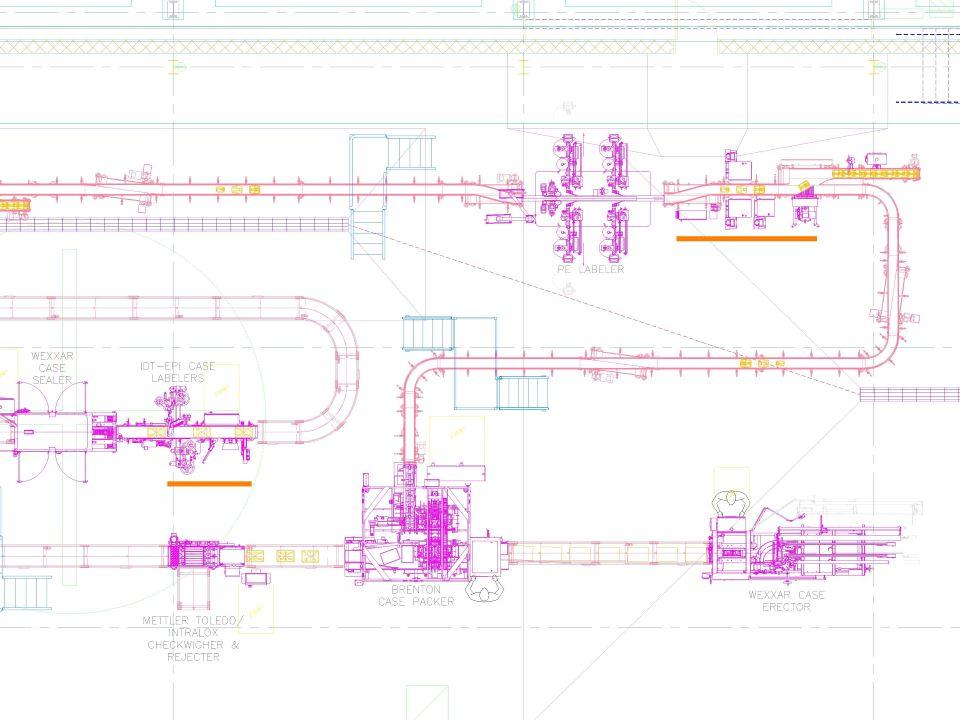

As a leading single source provider of turnkey processing and packaging lines, ProMach efficiently and cost-effectively helps customers of all sizes ship more packaged goods out the door. Our global team of technical application and engineering experts can transform individual pieces of equipment into high-performance production lines and help mitigate risk by partnering with customers to provide everything from line design to the end of the line.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFeatures & Benefits

- Identify and resolve issues prior to installation and start-up.Reduces ramp-up time to full production.

- Minimize financial and inventory impacts of lost production when replacing an existing packaging line.For projects that involve removing an existing packaging line and replacing it with a new line, vertical start-ups can save millions $$$ in lost production. Installation of the new line can begin as soon as the old line is removed and required utilities have been installed.

- Rapid start to pay-back process.Packaging line begins generating revenue, and providing a return on the investment, within days of installation.

- Identity and resolve challenges with new packaging applications, new packaging types and new packaging materials prior to start-up.Unforeseen challenges are identified and resolved on our shop floor, not yours which reduces risks and expenses associated with launching totally new product applications.

- Assures access to skilled and experienced commissioning resources.Reduces installation and start-up risks in areas, locations or facilities that lack the technical expertise to complete the implementation of a new packaging line.

Zarpac's turnkey design and management services are ideal for multiple applications: